“QAD’s methodology and guidance made the process of moving to the QAD Cloud, upgrading and opening a new plant smooth and successful.”

Laurence Headington, ICT Manager, Tsubakimoto UK Ltd.

Division launches new plant using QAD easy on boarding for move to the cloud and upgrade at existing site

The company: Tsubakimoto UK Ltd (Automotive division)

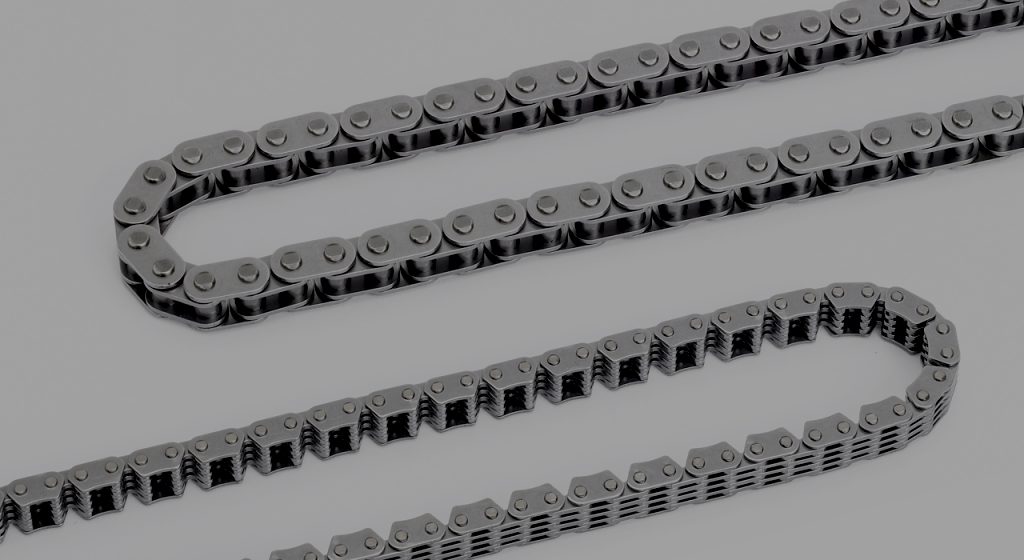

Tsubakimoto UK Ltd is part of the Tsubakimoto Chain Co, founded over 100 years ago in Osaka, Japan. A world-leading manufacturer of Automotive Parts and Timing Systems, Power Transmission Products and Materials Handling Systems. Tsubaki’s social mission is to exceed expectations while driving the evolution of the “art of moving”. The company is committed to developing products with unmatched technology for the ultimate in customisation to meet specific needs. Many of their products hold top market shares.

As a subsidiary of Tsubakimoto Europe b.v., Tsubakimoto UK Ltd manufacture and provide the world’s leading car manufacturers across the whole of Europe with automotive parts and timing chain systems for car engines and auxiliary drives. Recently and as a necessity due to increased capacity, a second plant was opened – Tsubaki Automotive Czech Republic s.r.o. – a purpose-built facility to manufacture and assemble timing chain drive systems and associated products.

The challenge: Expansion of the division drives the need for upgrading and a move to the Cloud

Tsubakimoto UK has been a QAD customer for many years using an on-premise solution until their recent move to the cloud.

While their on-premise system worked adequately for the existing scope of the UK division, the development and plans to build a new manufacturing facility in the Czech Republic greatly expanded the division’s needs.

Plans included the use of a common system between the UK and Czech sites with no local IT department at the new Czech plant.

“Since the new Czech plant was a fresh build that would not have an on-site IT department, we wanted it to be in the QAD Cloud and have the most up-to-date ERP system when it went live” comments Laurence Headington, ICT Manager, Tsubakimoto UK. “We also wanted an aligned system between both sites which meant the UK plant needed to be up-to-date.”

The Solution” Building a template for implementation of the new while upgrading the old

Working together with QAD, Tsubakimoto UK determined the most reliable and flexible solution was to first ‘lift and shift’ the UK plant’s current ERP version to the QAD Cloud.

Utilising QAD Easy On Boarding – a methodology based on industry best practices for companies seeking reductions in implementation time and cost of ownership – Tsubakimoto UK was able to create a template for use in their implementation at the Czech plant.

Once the move to the cloud was complete, Tsubakimoto UK took the opportunity to review and modify business practices where needed.

“With the guidance of the QAD team and the Easy On Boarding process, we put together exercises for developing process maps and created a Business Process Workbook at the UK site,” notes Headington.

“When we upgraded the UK plant to the latest version, the advance work we did with QAD helped to ensure all our business processes were implemented and fully documented in a consistent format.”

The workbook was then used at the Czech site as the basis for the new plant’s implementation – with all elements available as easily readable process flows.

This also allowed for a rigid and complete conference room pilot and user awareness training process with details about what testing was required for each process, as well as delineation of the responsible departments.

The first stages of the project including the ‘lift and shift’ to the QAD Cloud, evaluation of processes and the creation of the workbook took only four months. The upgrade was completed quickly and the implementation of the Czech site soon after – with ‘go live’ happening in just over three months.

“The Czech site is much like the UK site, producing and supplying similar products for the same customer base. It was agreed we would use the proven UK QAD ‘template’ as the basis for the ERP installation in the Czech Republic,” continues Headington. “Using the ‘template’ made the Czech plant implementation much easier, allowed for efficient training and ensured the configuration of the Czech system is virtually a mirror image of the UK site.”

The Benefits: Structured move to the QAD Cloud and upgrade results in mirror systems between established and new site

“Moving to QAD Cloud ERP has proven very reliable and consistent for us,” remarks Headington. “There has been minimal disruption which has helped in all areas of the company.”

“QAD’s approach to working through our gateways makes sense,” adds Owen Davis, supply chain manager, Tsubakimoto UK. “The quality of the end product is entirely dependent on how much effort you put into it and the structured and consistent approach QAD uses ensures nothing is missed, which is vital in a project such as this.”

As part of the upgrade project, Tsubakimoto UK also included QAD Cloud EDI. This removed the need for a multitude of EDI connections and on-premise EDI software.

“EDI is complex and critical, and outsourcing this to one service that handles all EDI and has the expertise to manage this in the timescales required has helped make our EDI a more reliable and resilient process,” notes Davis. “In addition, with the introduction of the Czech site, integrating their EDI requirements has been much easier than if we had done this on-premise. QAD helped make the transition seamless.”

“Tsubakimoto UK is now in a great position for moving into the future,” adds Headington.

Some of the areas Tsubakimoto UK is looking to use in the future are:

- QAD Automation Solutions for a more flexible and integrated data collection solution that will reduce the time spent recording inventory transactions and provide more control over label printing.

- QAD Channel Islands (QAD’s new UX initiative) for a consistent user interface and a solution that can be used on multiple devices.

“From my point of view it was all handled very well,” concludes Headington. “QAD has a methodology that is very thorough and very detailed. This was a major component in the success of the project.”

“Moving to QAD Cloud ERP makes us more flexible, agile and reliable.”

Laurence Headington, ICT Manager, Tsubakimoto UK Ltd