I am going through an awakening, a realisation. This is no sudden flash of light on the staycation road to Norfolk, but a gradual, stumbling focus on how I and the club to which I belong – ‘ERPers’ – can play a part in the major challenge the world faces: global warming and the need to cut emissions.

I cannot pretend to have a solid grasp of all the details and arguments. However, the situation is changing so rapidly that I think it is worth taking stock and setting out a few tentative conclusions.

Firstly the easy part: changes as a consumer. I allow myself to be guided to a certain extent to recycling and cutting out products whose harm to the environment is well published. There is always more I could do and there is a downside that even products that are environmentally credible have problems somewhere in their supply chain.

As an economic unit, I wasn’t altering my other side – a producer. However, I am now starting to realise that I have a part to play in that challenge too.

ERP’s role

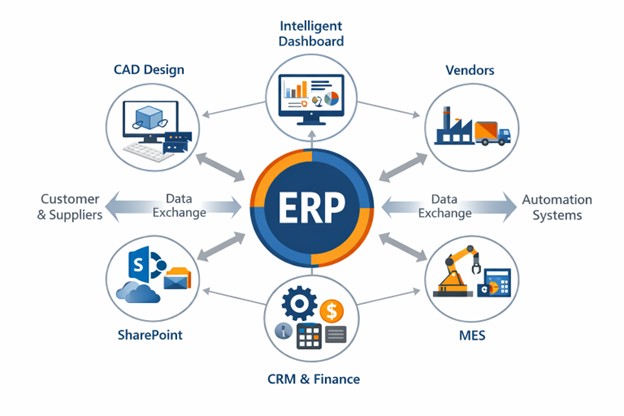

Firstly, let’s take a look at the field I work in – ERP. As you no doubt know, this acronym stands for Enterprise Resource Planning which means it facilitates how organisations exploit resources as efficiently as possible. Over the last 30 years it has enabled large-scale cost reduction in sectors ranging from oil and gas, to mining and retail. Waste was eliminated, raw material stock levels reduced, utility bills slashed. And it managed this at scale across the globe in a market valued at over $70bn a year, utilising the skills and expertise of hundreds of thousands of us.

The ERP market has helped clients master various challenges and opportunities along the way: client server, Y2K, the internet, reduction in trade barriers, global supply chains and increased digitalisation and cloudification. But I now would put forward a greater one – and forgive the grandiose nature: the planet.

The requirement

In a nutshell, despite the progress so far, mankind is not doing the right things quickly enough. To quote the Economist newspaper:

“To stay on track for net zero by 2030, annual production of electric vehicles needs to be ten times higher than it was last year and the number of roadside charging stations 31 times bigger.”

“By 2030, wind and solar farms need to be four times the pace of 2020, and clean energy investment will need to be three times its average of the past five years.”

“Scarce raw materials critical for energy saving devices – cobalt, lithium and nickel for batteries, copper for wiring and neodymium for magnets – will need to be tightly managed because demand is predicted to grow 9 or 10 times by 2050.”

Green shoots

So, what I now realise is that the field in which I work can play its part to enable more efficient use of these resources and to translate good ideas into action. And at the same scale as before and across an equally staggering range of organisations.

As I start to look around, I can see that we are already beginning to enable:

- New business models. Several automotive companies are now offering transport as a service, instead of only selling individual vehicles. This reduces CO2 emission and the demand for raw materials. But it requires significant changes to the supply chain such as the provision of regularly maintained and serviced vehicles at transport hubs. We can make these happen through changes in the ERP and associated business processes.

- Respond positively to reputational challenges. Fashion houses can no longer afford adverse reporting of destruction of old collections or of the devastation to regional water systems caused by intensive cotton farming. Instead, they are having to use raw materials even more efficiently and recycle as much as possible. Not only that, but they must provide proof of the new ethics of their supply chain. Again, only possible through a re-wiring of processes and systems.

- Ethical reporting. Provision of new information for ethical consumers who want to know the environmental cost of their consumption. Many beverage companies are responding by providing data on the carbon emissions per drink. And heaven help them if they don’t get this right!

- Continued market presence. The environmental regulations are (rightly) growing ever more stringent in many markets. Several agrochemical companies have to invest in biological products and ingredients in order to compete in Europe. Similar to the previous example, we can enable this through systems and processes that provide greater transparency.

- Recycle to avoid fines. Packages and consumer product companies are redesigning the majority of their products in response to taxes for single-use packaging. The reintroduction of material back into the supply chain requires some reconfiguration of existing processes and systems which we can manage.

- Data led decisions. Strategic sourcing or manufacturing decisions based on global sustainability objectives. Today many companies currently make decisions based on their financial cost and time and as a result, manufacturing is carried out at the most cost-effective locations. But as more weight is placed on sustainability factors, managers will demand a wider range of data from their ERP.

- New products produced in bulk. Wind farms and other energy mechanisms have to be produced in bulk, which means as old industries decline new ones are emerging. This large-scale production is built upon the efficient processes, flows of data and initiative systems that we can provide.

Some of the changes will have a direct impact on global CO2 emissions, others will improve sustainability factors. Many long-established organisations have to move from a linear model of raw materials to goods to sales and then it is someone else’s job to worry and pay for scrap and disposal. To keep up with the environmental pressure applied through society and regulators, these companies must embrace a circular model in which material is constantly recycled. Meanwhile, others launch new products and services in response to the small challenge.

To keep up with the environmental pressure applied through society and regulators, these companies must embrace a circular model

Conclusion

This new information and know-how will be at a premium. Indeed, in some quarters it already is because everyone is watching closely the early adopters and trend setters for hints and tips. We ERPers have our part to play. It is not just down to the scientists and inventers because good ideas need rapid application at scale to have a positive impact, as the current vaccination programme shows. Rapid and efficient deployment of new processes, systems and data is what we ERPers have been doing for years. Let’s apply that to the companies we serve and to the new economy. That way we play our part to help mankind overcome the greatest challenge yet. Together we might just make it.