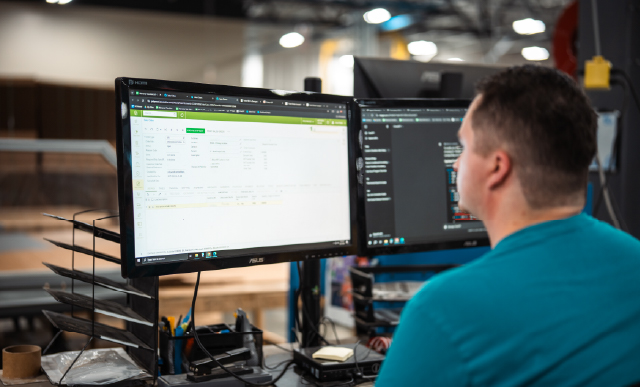

New private investors helped recycled plastic furniture maker POLYWOOD pump more than

$100 million into new facilities in the past seven years, which doubled its furniture and recycle plastic plant capacities. When the pandemic hit, a 10-fold increase in transactions illuminated the many flaws of its back-office legacy systems. POLYWOOD deployed Acumatica Enterprise Manufacturing Edition, gaining real-time data visibility and operational efficiencies that allowed the company to scale effortlessly.

KEY RESULTS

• Gained a real-time, flexible ERP platform, streamlining operations and eliminating

batch-processing

• Acquired a reliable platform that scales effortlessly as transactions soar

• Connected custom-made manufacturing execution system via flexible platform with open API

• Closed books faster by three days while gaining real-time data visibility

• Eliminated challenges that required office staff to help warehouse staff ship product

• Improved employee productivity with automated processes while eliminating printing of

Excel files

• Streamlined online order processing

• Improved shipping times increasing customer satisfaction

• United siloed applications, creating a single source of data and visibility across the company