Manufacturers are increasingly turning to smart manufacturing principles, hoping to convert the shop floor into highly efficient, data-driven operations that are humming with synchronized precision.

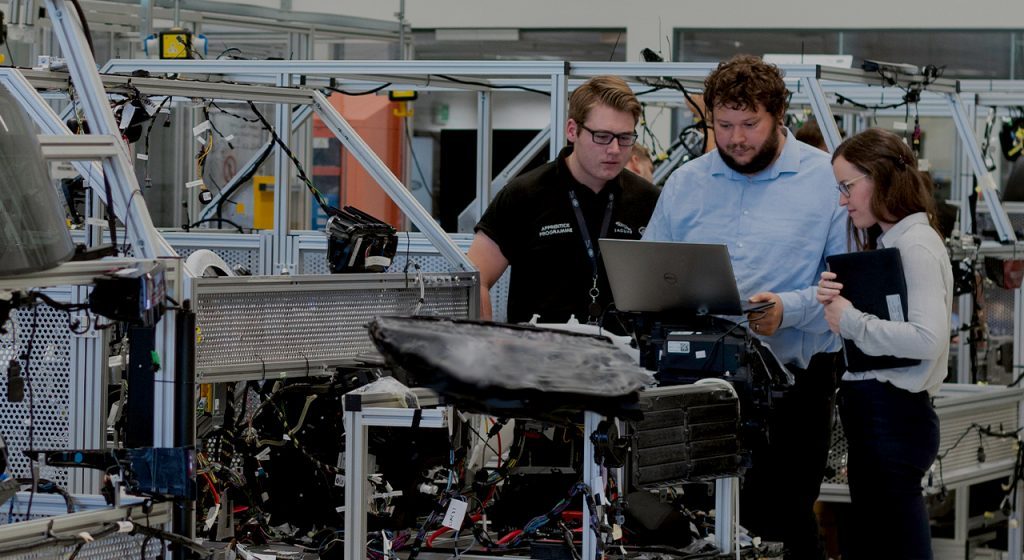

Unfortunately, line-of-business managers, crew leaders and shift supervisors – the shop floor heroes – often lack easy access to the ERP system and the relevant data needed to keep production on track.

Deskless workers play a vital role in operational efficiency and democratizing data, that is, making it accessible for a wider population, and can give front line users valuable decision-making insights. With role-based dashboards and reporting tools, they can drive better performance up and down the production line, from the smart use of resources to a reduction in rework and scrap.

Countless critical decisions are made on the shop floor every shift. The setting – notoriously noisy and fast-moving – isn’t conducive to careful, prolonged critical thinking. At the same time, errors can be costly, eroding profitability, wasting resources, and jeopardizing delivery schedules. Decisions based on guesses, a random exception or anecdotal stories can send a team into spirals of wasted time.

Empowering frontline users with democratized data interface tools

The answer is to put data in the hands of every decision-maker in the organization, even those who aren’t advanced data analysts. Modern digital platforms provide interface tools to help users apply advanced functionality to everyday situations.

Featuring low-code and no-code capabilities, the digital platform offers frontline users role-based dashboards to track relevant key performance indicators and custom reporting to investigate emerging trends. Dynamic insights are within fast reach of machine operators, maintenance technicians, material handling engineers, scheduling clerks and shift leaders.

Data to dodge workflow gaps and delays

Operational-level access to data is especially helpful in preventing workflow gaps and avoidable delays. Frontline workers can get immediate answers to design questions or specifications on a custom work order. Access to information keeps production lines moving as planned, with minimal interruptions because of questions, disconnects between departments or stockouts.

Advanced analytics can go even further to keep the shop floor operating smoothly and profitably. Managers can delve into exceptions and track influencing variables. They can find opportunities for improvement, such as eliminating quality roadblocks or controlling downtime.

Practical applications of AI in operations

As AI and machine learning have moved into the mainstream, manufacturers are increasingly seeking practical applications for data insights. Proof-of-concept projects are being replaced by ones that promise a timely, measurable return on investment. The shop floor offers many practical applications for AI-driven insights. Routine processes can be automated, streamlining the need for human interaction. Only anomalies or exceptions need to be routed to supervisors for individual attention. Streamlining the data flow will also help keep various teams apprised of real-time updates and needs. This approach means that no one is out of the information loop, falling behind on evolving expectations. One data-driven digital thread can connect every stage in shop floor operations.

How democratized data helps boost productivity for operations:

Custom quotes and bills of materials

Automating the process for generating rules-based quotes across make-to-order, engineer-to-order and configured products allows for a seamless journey through the sales workflow from the point of order to successful delivery.

Projecting raw resources needed

Synchronizing production planning and availability of raw resources using data and AI-driven predictive capabilities can prevent stock-outs and keep procurement managers informed.

Accurate scheduling

Synchronizing production runs to fulfill customer orders alongside sales, delivery promises, raw materials inventory third-party interface and machine capacity. Collaboration portals can help share information while protecting security.

Strategic workforce scheduling

Data insights can assist managers to keep on top of today’s acute labor shortage by tracking and understanding the performance of shifts and crews, identifying essential staffing requirements and monitoring expenses.

Workflows

By coordinating teams and sharing data on job status, equipment performance and scheduling, democratized data can allow operations to run smoothly with no gaps, delays or roadblocks.

Compliance and quality control

Democratized data helps managers track, monitor and evaluate quality standards and compliance requirements with a continuous feedback loop in place. As new products are introduced, specifications are able to easily be updated and accessible to relevant teams.

Waste reduction

Access to and improved consistency of data will reduce waste and help crews verify proper machine settings, consult knowledge banks for typical resolutions of issues, and verify proper specifications and variables.

The call center

Real-time access to account, service location and product details can answer the customer questions about deliveries, service agreements, warranty status and scheduled preventive maintenance required on the aftermarket.

First-call resolution

Field technicians need access to details on the unit, as-serviced history, inventory status of parts and availability of replacement or upgrade units. A technician with the right data is seen as a trusted advisor and can often make sales in the field.

Next steps for your software

Manufacturers considering deploying their first ERP solution or upgrading a legacy solution often compare various vendors and the functionality of their solutions but usability and accessible data shouldn’t be forgotten.

Some solutions offer built-in industry-specific functionality and make usability and democratized data a top priority across operations. Easy access to data is essential and a characteristic to look for in a smart ERP selection.