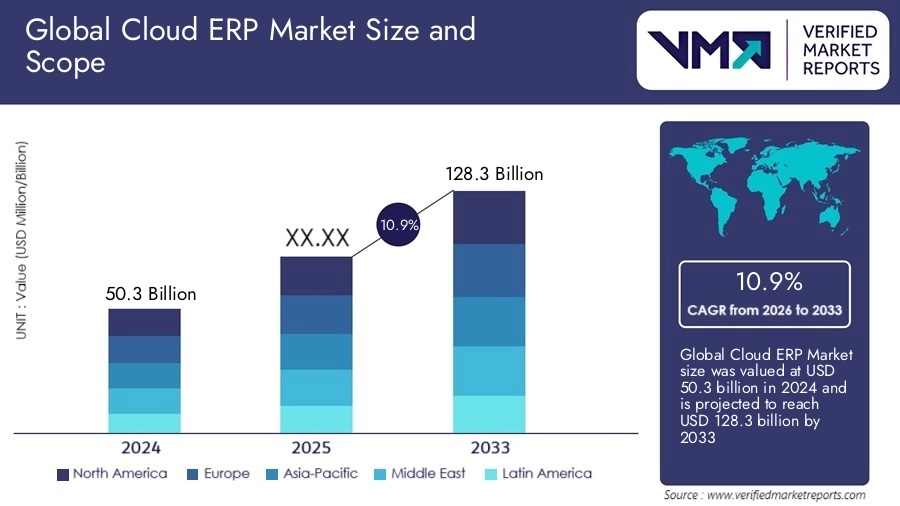

Cloud-based ERP platforms are shifting manufacturing operations from reactive firefighting to predictable, stable workflows built on connected, data-driven processes. The manufacturing ERP market is projected to reach approximately $23 billion in 2025, growing around 8% annually as manufacturers invest in Industry 4.0, IoT integration and supply chain optimization.

For technology executives, the transformation is not about adding dashboards but fundamentally changing how teams spend their time. They’re moving from manual reconciliation and crisis response to continuous improvement and strategic integration work.

Automating Manual Processes to Reclaim Operational Capacity

Cloud ERP implementations deliver measurable productivity gains by eliminating clerical friction and reducing manual intervention across manufacturing workflows. A shipbuilding organization that shifted from mostly manual to fully integrated cloud ERP reduced manual intervention to approximately 5% of processes and anticipates millions in annual savings from better purchasing controls and process discipline.

Production schedules in cloud ERP environments update finance forecasts in real time, keeping cash flow, budgets and capacity planning aligned without manual reporting. Inventory counts flow automatically from warehouse to purchasing, so buyers see stock levels instantly and can replenish before shortages cause delays. Quality checks integrate with compliance records instantly, reducing audit preparation time and making regulatory reporting effortless.

These automation patterns change daily work for operations leaders, as effort shifts from reconciling data and chasing approvals to designing better workflows and integration patterns that keep material, capacity and demand synchronized.

Strengthening Supply Chain Visibility and Logistics Performance

Cloud-native architectures provide the real-time data access and role-based dashboards that technology leaders need to spot shortages, delays and quality issues early and re-plan quickly. Integrated planning, execution and reporting capabilities within cloud ERP enable automated demand forecasting and replenishment planning using historical and real-time data, optimizing inventory management and reducing reaction times from days to minutes. Sales orders sync with the shop floor, ensuring production teams have the latest demand data without double entry, while supplier portal updates feed straight into procurement, streamlining approvals, lead times and shipment tracking.

For example, a ventilator producer that reconfigured its operations on a configurable cloud ERP platform scaled throughput roughly 80 times in a matter of months to meet a federal order, demonstrating how a stable, data-rich backbone can support extreme agility without disrupting operations.

In another case, The Metalworking Group increased on-time delivery rates to 86% from 75% within 12 months of implementing cloud-based industrial manufacturing ERP, while chemical manufacturer The Hammond Group reduced IT costs by 39% in the first year of upgrading to cloud process manufacturing ERP. These improvements in logistics performance and delivery reliability stem from unified, real-time visibility across production, inventory and supplier networks that on-premises systems cannot match.

Prioritizing Integration Depth and Organizational Readiness

When evaluating cloud ERP providers, technology executives are emphasizing extensibility through APIs, event frameworks and low-code tools as much as core functionality. Platforms that expose robust REST and SOAP interfaces and offer proven patterns for connecting to CRM, MES, e-commerce and financial systems reduce the integration tax and lower long-term risk.

Successful adopters tend to follow a staged roadmap, codifying business objectives, mapping data across legacy and new systems and governing integration scope so new capabilities do not reintroduce the very instability they were meant to remove.

Adoption challenges are shifting from pure technology questions to organizational readiness, as high implementation and maintenance costs, along with skills shortages, still constrain smaller manufacturers even as cloud options lower infrastructure barriers. Organizations that overcome these barriers emphasize cross-functional governance, phased rollouts and clear data quality standards before attempting large-scale migrations. Cloud manufacturing ERPs are designed to deliver tangible business value with deployments completed within weeks.

What This Means for ERP Insiders

Operational ROI narratives are becoming more granular and timebound. Vendors and system integrators that quantify labor hours removed, capital released and cycle times shortened, down to specific workflows and timeframes, will gain credibility with CFOs and plant leaders, reshaping buying decisions and influencing product roadmaps toward measurable, modular value delivery.

Integration strategy is emerging as a core governance domain. Technology leaders will formalize patterns, standards and ownership for ERP-centric integration, forcing closer alignment between ERP vendors, iPaaS providers and SIs and elevating data modeling, API management and change control as primary levers of operational stability.

Cloud-native architectures are becoming the default. Architectural discipline will separate winners from reactive implementers, as technology leaders who treat ERP as an operational backbone rather than a transactional database will push vendors toward open, event-driven architectures that can absorb IoT, AI and edge workloads without sacrificing stability or maintainability.