The Company:

QAD PROCESS INTELLIGENCE SAVED OVER $500K IN SIX MONTHS BY REVEALING PEAK PERIOD INEFFICIENCIES

A French multinational retail and wholesaling corporation with $20 billion in revenue, wanted to decrease the number of incomplete shipments, save time on the global delivery process and calculate a compliance per rush time / normal.

The Challenge:

SUPPLY CHAIN COMPLEXITIES CAUSING INEFFICIENT ORDER PREPARATION PROCESS

Supply chain challenges are a daily reality for this company. The Head of Supply Chain describes the complex job in simple terms:

“I receive goods, I prepare the orders, then I ship them. My trucks leave every day at noon and except for exceptional delivery, I deliver on time. However, 5% of my delivered shipments could be partial (incomplete) in rush time and I have to double the workforce. Moreover, traditional KPIs are unable to identify specifically how to decrease the non-compliant journeys and where to save money in the process.”

The Solution:

QAD PROCESS INTELLIGENCE ANTICIPATES IMPORTANT DEVIATIONS AT THE BEGINNING OF BUSINESS FLOWS

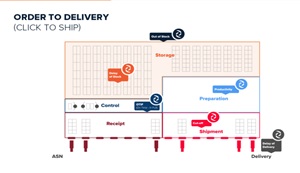

QAD Process Intelligence showed the logistics process as it really happens in the warehouse and during delivery. This was possible thanks to data coming from the WMS, OMS and TMS. A solution that provides “hypervision” at global and individual event levels was the only way to start working on process issues.

Then Process Intelligence was able to find all deviations of the original processes during the “peak” periods and identified the most expensive ones by selecting these different KPIs:

- PPIs (Process Performance Indicators)

- Non-Compliance

- Reworks

- Loops

- Journey time

- Business Indicators

- Supply in time

- On time in full

- Productivity

- Stock image

- Delay on stock

Several corrective actions were identified and important deviations were anticipated at the beginning of business flows thanks to QAD Process Intelligence providing real-time alerts.

The Benefits:

UNPRECEDENTED WAYS TO IDENTIFY LOSSES THROUGH HYPERVISION AT GLOBAL AND INDIVIDUAL EVENT LEVELS

By identifying those issues, QAD Process Intelligence enabled the customer to quickly save hours in the order preparation process. Global Supply Chains have different levels of actions:

In the short term, QAD Process Intelligence was able to make quick wins and saved more than $540,000 in less than six months of implementation.

In the longer term, global processes can be revised to include automation to embed continuous efficiency and consistency into business flows.