The manufacturing industry is experiencing a transformation just as much as any other industry in today’s morphing tech-scape. An intriguing development in this space is the recently announced partnership between NTT DATA and Alloyed, which seeks to further 3D metal-printing technologies in the Japanese market. This collaboration aims to leverage the distinct strengths of both companies to drive advancement in manufacturing processes.

NTT DATA is known for its expertise in digital transformation, including advanced IT infrastructure, cloud computing and data analytics. Its role in the partnership is to enhance Alloyed’s additive manufacturing (AM) processes through these technologies. By integrating NTT DATA XAM Technology’s digital tools, Alloyed will have the ability to optimize its metal-printing techniques, streamline production and accelerate the development of new materials. Additionally, NTT DATA’s global network and market presence offer Alloyed expanded access to Japanese markets and customer segments.

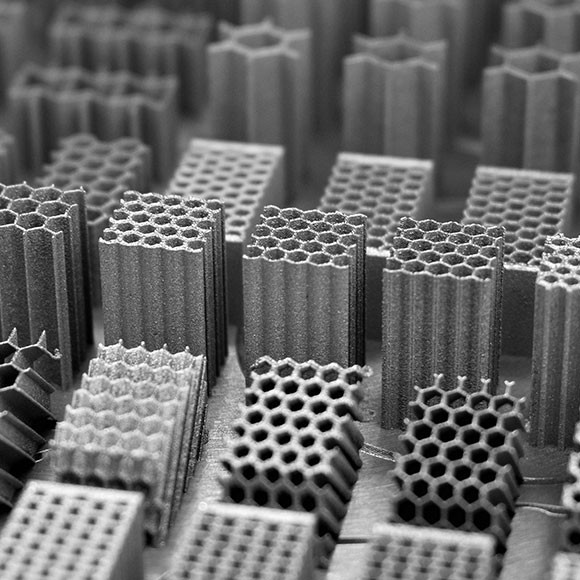

The move towards AM is particularly impactful in industries that require highly specialized and high-performance materials, such as aerospace, automotive, medical devices and industrial machinery. For these sectors, the ability to produce lightweight, durable parts that can withstand extreme conditions is critical. AM technology not only facilitates the production of such components but also offers the flexibility to innovate in design, leading to more efficient and optimized products. For instance, in the aerospace industry, AM enables the creation of parts with complex geometries that are not possible through traditional manufacturing, resulting in lighter aircraft and reduced fuel consumption.

Sustainability is another critical driver in the evolution of the manufacturing industry. As global awareness of environmental issues grows, there is increasing pressure on manufacturers to reduce their carbon footprint and minimize waste. AM, with its ability to use materials more efficiently and reduce the need for extensive machining and assembly, is a key technology in achieving these sustainability goals. The capability to recycle and reuse materials in the AM process further enhances its environmental benefits, making it an attractive option for industries committed to reducing their environmental impact.

For companies like NTT DATA, which are at the forefront of digital and technological innovation, investing in advanced manufacturing capabilities is a strategic move. It positions them to capitalize on the growing demand for high-tech solutions and supports their users in navigating the complex landscape of modern manufacturing. As the industry continues to evolve, the ability to offer cutting-edge AM solutions will be a key differentiator for companies seeking to lead in innovation and sustainability.

Addressing the end user, Kenichi Mizunuma, president and CEO, NTT DATA XAM Technologies, said: “We eagerly anticipate deepening our business collaboration and contributing to the technological innovation of our manufacturing clients. By integrating Alloyed’s outstanding knowledge in alloy development, extensive material data, thermal management design capabilities, and more, with our proficiency in quality certification and digitalization through advanced process monitoring, we have gained a significant competitive edge. This partnership underscores our commitment to advancing AM technology as a viable production method, positioning us to contribute to the revitalization of the domestic and global markets.”

Michael Holmes, CEO of Alloyed, said: “Alloyed’s technologies are about achieving more and more performance with less and less metal, and that theme is highly consistent with Japan’s industrial imperatives. I’m convinced NTT DATA XAM Technologies is the right partner to bring this technology to the Japanese market.”